Post-weld Heat Treatment of welded Al-2024 alloys and their fatigue behavior

PhD Student: Mr. Vinay Kr. Yadav

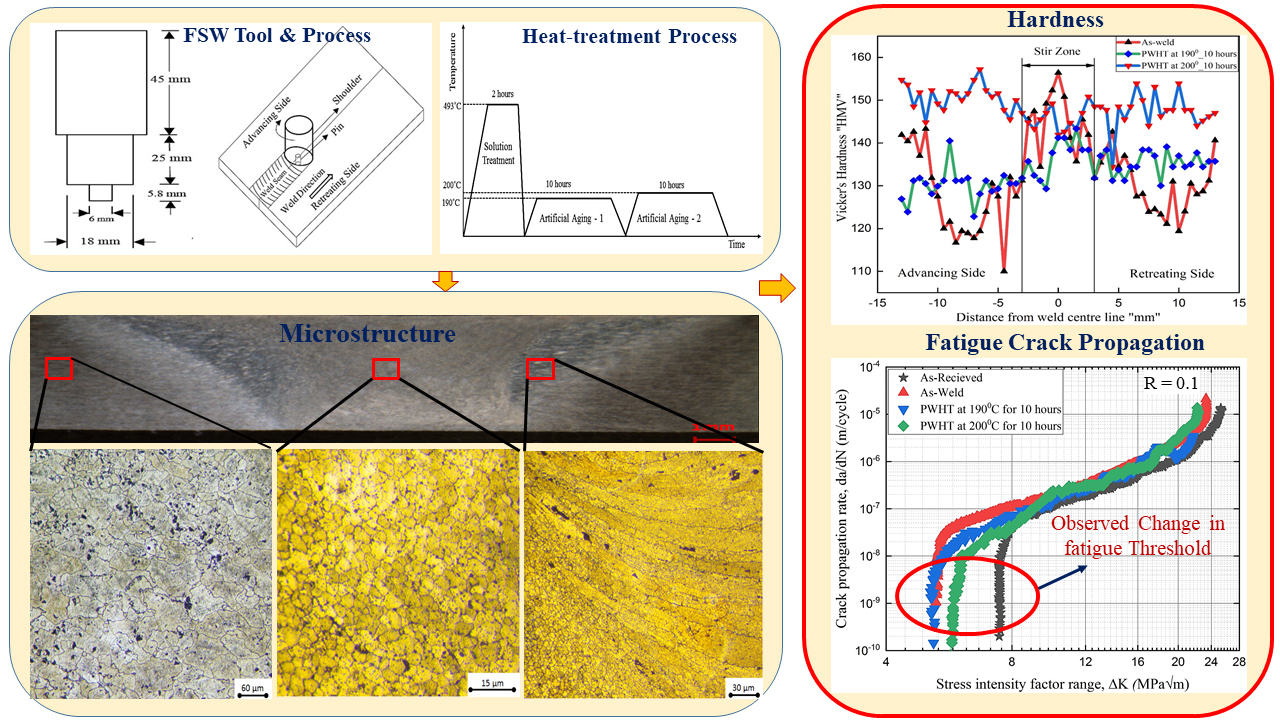

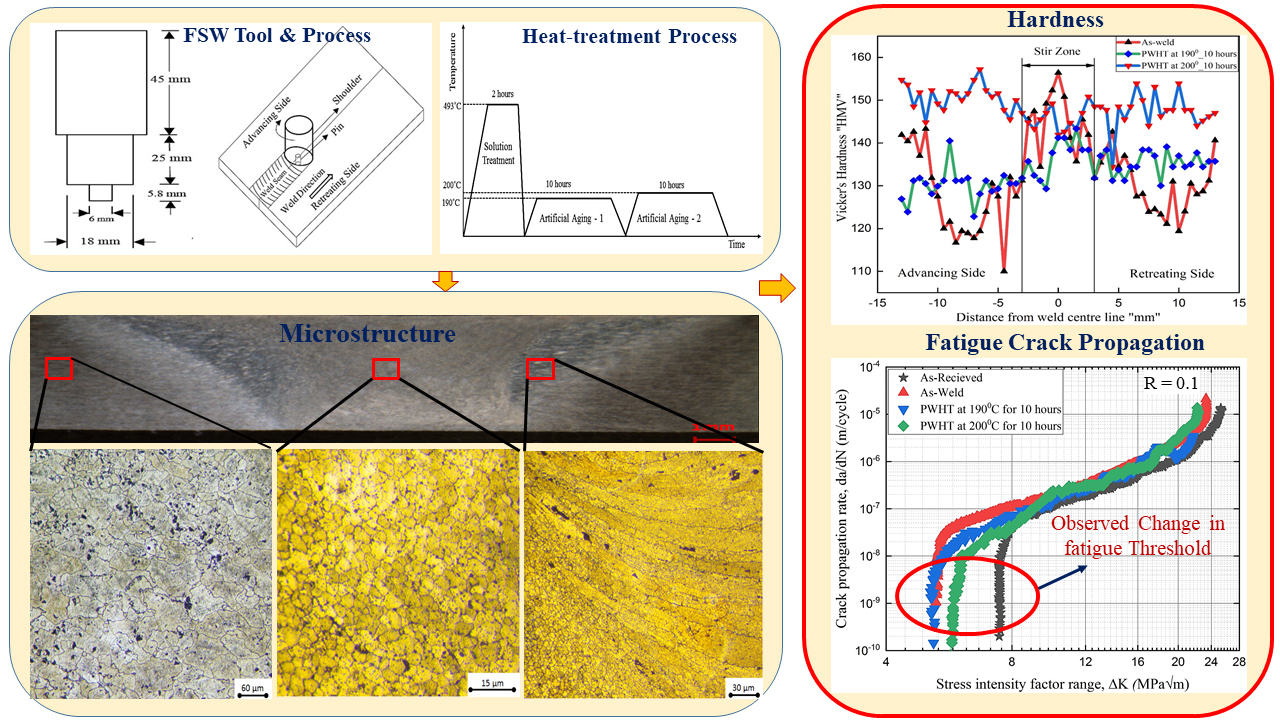

In this study, effect of post weld heat-treatment (PWHT) at two different aged temperatures was investigated on the microstructure and the material properties of the aluminum alloy 2024. The plates of AA2024 were welded using friction stir welding process, followed by PWHT at different aged conditions: 190 for 10 hrs and 200 for 10 hrs. Both tensile and cyclic properties were investigated. PWHT at 200$\celsius$-10 hours resulted in significant changes in the microstructure and improvement in the mechanical properties of the welded joint. PWHT resulted in re-precipitation of the precipitates, specifically in the thermo-mechanically affected zone (TMAZ) & nugget zone (NZ) but no significant abnormal grain growth was observed in the nugget zone. A significant improvement in the ductility and the hardness of welded joint was observed for PWHT at 200 – 10 hours. Long crack growth tests were conducted using sinusoidal loading of 10 Hz frequency and at a stress ratio of 0.1. The PWHT joint at 200 – 10 hours resulted in higher threshold stress intensity factor range () as compared to as-welded joint and the PWHT joint at 190 – 10 hours. The observations are explained based on microstructural changes in the FSW joint.